Who won the Nobel Prize in Chemistry 2025?

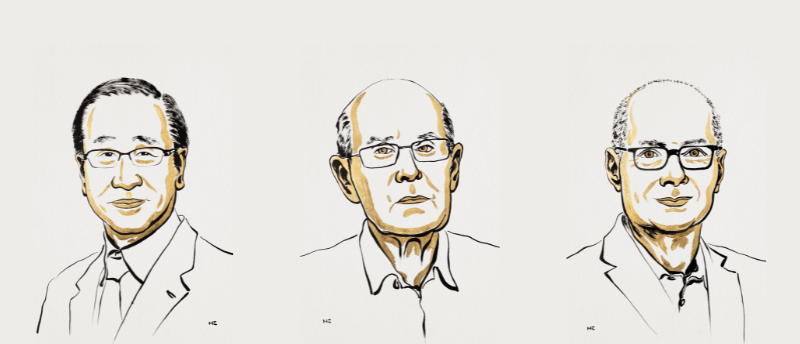

Metal-organic frameworks, a near boundless group of functional materials that faced years of apathy, are the focal point of this year’s prize. The Nobel Prize in Chemistry 2025 has been awarded to Susumu Kitagawa (Kyoto University, Japan), Richard Robson (University of Melbourne, Melbourne, Australia) and Omar Yaghi (University of California, Berkeley, CA, USA) for their contributions to the discovery and development of metal-organic frameworks. In 1974, Richard Robson was tasked with creating models composed of wooden balls and poles with which students at the University of Melbourne could create molecular structures. In the process, he instructed the university’s workshop to...

To view this content, please register now for access

Join our member community for FREE to access a collection of journal and online-only features, including:

- Exclusive access to educational videos, eBooks and insights into top BioTechniques journal articles

- The latest news and journal updates delivered straight to your inbox when you want it

- Personalized recommendations for the latest member-exclusive podcasts, interviews and expert opinions

- Priority registration to webinars, panel discussions and events

- Access to competitions and journal publication discounts, including 10% off open access fees when you sign up today!