Building a LEGO lab with Cassandra Quave

BioTechniques Digital Editor, Tristan Free talks to Cassandra Quave of Emory University (GA, USA) about her research analyzing botanical natural products to determine their pharmacological potential. Cassandra also tells us about her team’s recent step into engineering to solve some of the lab’s issues with workflow, where she went digging in her child’s toy box to create an automated fraction collector predominantly made out of LEGO™ (Billund, Denmark).

Please can you introduce yourself, research background and current research interests?

My name is Dr. Cassandra Quave. I’m an Assistant Professor of Dermatology and Human Health at Emory where I also serve as a curator of the Emory University Herbarium. I lead a research group that is dedicated to the documentation of traditional medicines and also the collection and biological evaluation of medicinal plant species for their potential pharmaceutical value. We are interested in looking to nature to find new solutions for some of our greatest emerging disease threats. We look at plants that are used in traditional medicines for the treatment of infectious and inflammatory disease in order to discover potentially new chemical scaffolds for the treatment of antibiotic resistant infections.

My name is Dr. Cassandra Quave. I’m an Assistant Professor of Dermatology and Human Health at Emory where I also serve as a curator of the Emory University Herbarium. I lead a research group that is dedicated to the documentation of traditional medicines and also the collection and biological evaluation of medicinal plant species for their potential pharmaceutical value. We are interested in looking to nature to find new solutions for some of our greatest emerging disease threats. We look at plants that are used in traditional medicines for the treatment of infectious and inflammatory disease in order to discover potentially new chemical scaffolds for the treatment of antibiotic resistant infections.

Can you tell us about your recent publication in Analytical Chemistry regarding the LEGO MINDSTORMS fraction collector?

One of the major bottlenecks to research on botanical natural products is the isolation of sufficient compounds for structural elucidation. In my laboratory, one of the processes that we use is to collect plants and then extract compounds from them using organic solvents to create a crude extract. Using leaf tissue as an example, we take 40g of leaf tissue, dry and grind it up, and then extract it in an organic solvent. Once that dries down, what we find is hundreds if not thousands of different molecules, which are screened together for bioactivity. Our challenge then is determining which of those molecules is responsible for the bioactivity that we are seeking. Sometimes your bioactive compounds are only present in less than 1% of your overall mixture of the natural products.

We use a lot of different tools in chromatography to separate the compounds; tools like flash chromatography, liquid—liquid partitioning and then also lots of analytical and preparative high-performance liquid chromatography (HPLC). To overcome the bottleneck of isolating sufficient qualities of compound, we often find that, after several steps of purification or cleanup through flash chromatography, we actually will need to run those preparative separations many times – in some cases up to 15 runs – in order to yield sufficient quantities of bioactive molecules for confirmation studies in our biological assays and then also for our structure determination studies. In these studies, we are using tools like mass spectrometry, NMR and even x-ray crystallography.

One of the challenges is basically enabling your HPLC system to collect over, over and over again in this interactive fashion, without requiring intensive personnel involvement throughout the day as the machine runs. So, the inspiration of this project really came in one afternoon when I arrived at the lab and noted that one of my postdoctoral research fellows was sitting at the machine watching the clock and manually collecting fractions. This is something that many labs I’m sure are very familiar with. She had been doing this for several hours, watching the clock and manually moving the liquid jar to jar over different time gradients. So I just made the comment of “surely we can do something better than having a person actually manually collect these,” and I’m really trying to foster an environment of creativity in the lab, so we get to talking about this with other members of the research team. One of our research technicians who actually does a lot of the electronics and carpentry work in our group said that he thought he had an idea and wanted to explore the idea of using LEGOs as a platform. We were looking for a setup that would be customizable to our needs and also something that would be relatively inexpensive. A large-scale open-bed fraction collector that’s purchased from a standard supplier can range in cost from $10,000 to $20,000, depending on what the brand is and what its capacities are, and we wanted to create our own collector for under $500.

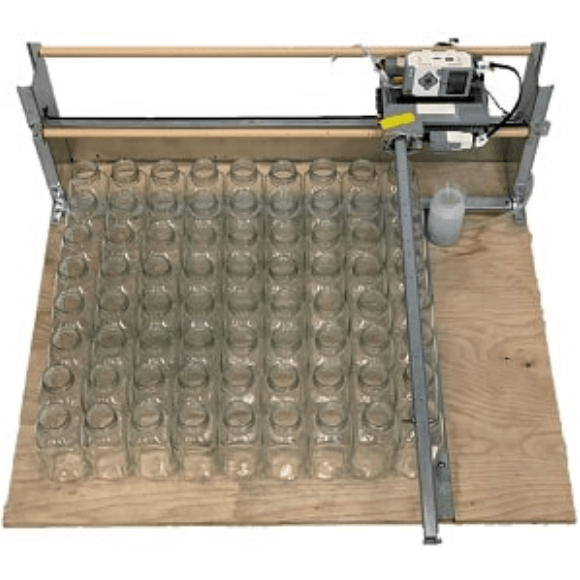

Basically, through looking at different types of fraction collector models, he was able to create this unit that would then move back and forth on a pulley system. He constructed the base of the unit out of just wood and then used a C-shaped metal to create the upper part of the frame. We ultimately decided to use the LEGO MINDSTORMS unit because of the ease of programming. There is open access software that’s available so, even if you don’t have a background in computer programming, it is pretty simple to learn how to use that software with your unit. That’s what we did; we built it and then recorded all the different steps. The LEGO company also has a nice application that you can use that will enable you to record how each of the LEGO pieces is put together. Within our publication is a link to supplementary files which include detailed step-by-step instructions on how to actually build the entire unit, from start to finish. We also included instructions on how to build the base and the frame using some supplies that you can access in really any kind of basic hardware store. Lastly, we created a video to illustrate how all of the parts are pulled together, and posted it on YouTube.

The reason I felt that it was important to publish this and not to just leave it as a cool lab trick was that we actually do a lot of work with collaborators across the globe, including in places that are very resource-poor when it comes to scientific infrastructure in universities. From my travels and work with these amazing scientists in different countries, I have noticed that any solutions that can be created based on low-cost materials can really make a big impact on their research capacity. So that’s why I thought that was important also to publish this innovation as a technical note in a prominent chemistry journal.

In research, emphasis is often put on the resulting discovery rather than the new technologies that made it possible. Is it time to focus on the tech?

Were you also trying to prove a point about costs with the LEGO MINDSTORMS construction or was it just the most practical path available to you?

Yes, I think it was just really that I did not have a spare $20,000 lying around the lab. We are always looking for solutions that can improve throughput and reduce unnecessary manual labor in the lab because I really wanted to see my researchers, my scientists, postdoctoral fellows and graduate students using their time and minds towards problem solving and other experiments that do require more manual intervention. This just seems like a really good place to start with implementing a customized automation unit to the lab.

You mentioned that you have the supplementary materials attached to the paper, are there any plans to roll out the system as a patented model?

We briefly thought about the idea of trying to patent something like this, but honestly, it’s built on LEGO technology, so I don’t know if a patent is even a possibility there. Also, what I feel really strongly about was that I wanted to make this accessible to other scientists that don’t have access to those very expensive types of equipment that this is replacing. This is not just in other countries, there are plenty of examples of scientists here in the USA that could benefit from this, especially institutions that are primarily undergraduate teaching focused. It could be implemented in research laboratories; it could be in teaching laboratories; it could be useful for basically anyone doing any kind of separation chemistry, so it’s not limited to people that do work with preparative HPLC. The nice thing about this device is you can hook it up to really any kind of chromatography set up where you have a mobile phase that’s coming off your column. Another example is this could be used with a gravity column, just a glass column that’s very standard in a lot of places where you are separating either natural products or the products of synthetic chemistry.

Do you have any tips for best practice whilst you’re using the fraction collector or setting it up?

There are a lot of pieces so it will be a bit challenging to assemble it, but we have provided a lot of resources to guide users as they do so. In addition to the written supplementary instructions – which are available freely, it does cost to get access to the Analytical Chemistry article, but the supplementary instructions that include all the details for creation of the unit are free – we also included a link to a free YouTube video, which physically shows how we put together the different parts of the unit so that it can be even more accessible. So, if there is any difficulty understanding the written instructions, you can also watch this video as a supplement to installing it.

For best practices, it’s pretty straightforward once you have it set up. Again using that open access LEGO MINDSTORM software, there are many resources online, including free tutorials on how to use it. We are also currently working on iteration number two which will be run off of an Arduino computer device using C++ programming. We are doing that primarily because we thought it might be fun to see what other ways there are that we could do this. Also, it is at an even lower cost, but there is more needed on the development end to get the software going. However, with this first iteration I think once you have it assembled it is quite simple to use and is very adaptable to different types of chromatographic systems.

Are there any limitations to the system that you find compared to the more expensive systems for automating the fraction collector?

One of the limitations is that it’s not integrated with the HPLC software. It’s a separate software set up that runs it. There is a bit of method development in the beginning as you determine how to set up your fractions. There are other fraction collector units that are available on the commercial markets that do allow for integration with the HPLC software, that can basically make decisions on when to collect and can determine different collection times based on peaks that pop up in the chromatogram. This system does not do that.

One of the things that I would say would be useful as an addition to the current platform that we’ve developed is perhaps to create a cover for the unit. In situations where you have a lot of dust, or especially for those labs that work with plant powders, there could be a potential issue where you could get dust or other small particles from the air landing into the open collection vessels. A simple option is basically to create a simple transparent plastic cover or box to put on top of the unit to prevent or reduce any dust particle contamination of the vessels.

The soil microbiome: a ticking time bomb for climate change

The soil microbiome: a ticking time bomb for climate change

BioTechniques talks to microbiome expert Janet Jansson about the carbon density of the soil microbiomes around the world, how humans are damaging it and how we can begin to turn the tide.

Since you have developed the system, has it allowed you to make any big steps forward with your research or is it mainly just accelerating that workflow process?

Yes, I mean it actually has led to some really great advances in our research. When I was training as a PhD, the idea of getting an X-ray crystal structure of an isolated natural product was just not very common and I was always told that it was just too difficult to do because you need to purify such a large amount of the compounds to get a good single crystal X-ray diffraction on it. Since implementing the system, we have actually been able to isolate a number of bioactive compounds and get their crystal structures. We recently published a paper on the first crystal structure of the anticancer natural product genkwanin isolated from Callicarpa americana, or the American beautyberry. We also recently found crystal structures on four compounds that work as anti-bacterial compounds against staphylococcal infections. These act by blocking virulence pathways in Staphylococcus aureus. One of these papers is in preparation and the other is currently in review right now, but yes that’s the most exciting event; not only are we isolating enough of these compounds to determine their structures by classic mass spectrometry and NMR experiments, but we’ve also been able to get pure enough compounds through this method. Again, we’ve been running it iteratively, just through brute force separation many, many times using the robotic device and now we are getting crystal structures on compounds that have never been crystallized before and that’s really exciting.

In your research, are there any groups of plants that particularly or continually surprise you in their capabilities?

Yes, we’ve been building upon some research that was started a number of years ago on two species that had really captured my interest. One is the Brazilian peppertree; its scientific name is Schinus terebinthifolia. This is a plant that has a very long history of use in the Brazilian pharmacopeia, but in the USA, especially in the southern parts, it grows as an invasive, noxious weed. So I have been looking more and more into the chemical and biological activity of different tissues from that plant and one of the papers that I mentioned that’s currently in review includes the three crystal structures that we have isolated those active compounds from that plant.

We are working on isolating compounds from Castanea sativa, also known as the European chestnut or the sweet chestnut. This is building on some research we initially published back in 2015 where we were able to see some of interesting anti-virulence properties of excerpts from these leaves. There are a number of other plants we are also working on. Unfortunately, I can’t talk too much about them because there are still undergoing patent protection processes that have to come into play before I can give a public disclosure, but I think there are a number of really interesting species and families in general that are starting to catch my interest. We are also currently working on one of the largest reviews ever attempted on the anti-microbial activities of plants. We reviewed over 3,900 scientific articles, going back to 2012, that had each documented the bioactivities for both plant extracts and isolated compounds against different human pathogenic bacteria. That is a major project my lab has been involved in that we hope to complete and submit in March for publication with a major chemistry journal.

Regarding the anti-microbial properties of the sweet chestnut, can you say which microbes they are targeting?

What we found were compounds that did not necessarily inhibit bacterial growth, instead they work by blocking virulence pathways in S. aureus. In other words, they stop the production of toxins that cause damage to your tissue. We’ve also done a good deal of work on another plant, Rubus ulmifolius, or the elm leaf blackberry, and that one has shown activity in blocking bacterial biofilm formation in both S. aureus and Streptococcus pneumoniae. Biofilms are formed by bacteria in order to stick to surfaces and this makes infections incredibly difficult to treat. We’re also exploring development of the formulation that we have isolated from blackberry roots and developing that into a medicated bandage, along with a company that we teamed up with.

Is there anything else that you would like to add?

One of the greatest joys of science is the ability to collaborate both locally and internationally and it has really taught me to value the importance of access to scientific tools. I would encourage any scientists that had some innovative ideas on how to make key resources more accessible to our peers across the globe to pursue them because there is a lot out there still to be explored and we need more people undertaking scientific research, especially in the space of understanding the pharmacological potential of plants.

A hammer doesn’t need a nail

A hammer doesn’t need a nail