Accelerating coral reef recovery with 3D printing

Researchers have developed new technologies to create a carbonate skeleton that could substantially speed up the rate of coral growth.

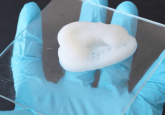

A team of researchers from the King Abdullah University of Science & Technology (KAUST; Thuwal, Saudi Arabia), led by Charlotte Hauser, has developed an active approach to the restoration of coral reefs through the use of 3D printing. The key to the approach is a new 3D ink that provides coral with a calcium carbonate skeleton to grow on, giving it a head start and leading to faster growth.

Global warming, ocean acidification, rising sea temperatures and human impact have all had a negative effect on the overall marine environment and coral reefs. Scientists have employed several methods to combat these negative effects such as using concrete blocks or metal frames as a layer for coral growth. However, coral grows at a rate of a few millimeters per year by slowly depositing a carbonate skeleton making this method slow and ineffective.

The use of 3D printing to provide a support structure for coral growth has been tested in the past. This has usually been through the use of synthetic or hybrid materials which passively allow the coral to colonize and grow on them. However, researchers from KAUST have developed new technologies that take a more active approach.

Climate change, temperature and tuna

Climate change, temperature and tuna

The evolutionary advantage of warm blooded fish have hoodwinked marine biologists for some time, especially as this seems to occur in only a few species.

The team has developed a calcium carbonate photo-initiated (CCP) ink, which provides coral with a carbonate skeleton, and 3D CoraPrint, which allows them to attach coral microfragments to the skeleton to start the growth process. This combination takes out some of the work for the coral, aiding in and encouraging faster coral reef regrowth.

Current tests have shown that CCP is ecofriendly, sustainable and nontoxic, though longer-term tests will be carried out by the researchers.

These technologies can be used in two different ways, both of which have their advantages and disadvantages. For the first method, a scanned model of a coral skeleton is printed and used to create a silicon mold after which the mold is filled with CCP ink. This method makes the process quick but limits the size of the mold and the resulting coral skeleton.

The second method is direct printing, where the coral support skeleton is printed using the CCP ink without a mold. This process is slower but means that the structure can be bigger and customized for the reef.

Zainab Khan, a lead author on the study said, “with 3D printing and molds, we can get both flexibility and mimicry of what’s already going on in nature. The structure and process can be as close as possible to nature. Our goal is to facilitate that.”