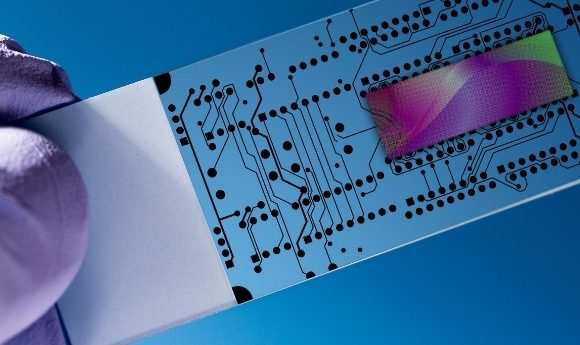

Mixing liquids for microfluidics

Microfluidics takes a new step – an infinitely reconfigurable, 3D-printed, all-liquid lab on a chip.

A team of researchers from the Lawrence Berkeley National Laboratory (CA, USA) has produced an all-liquid 3D-printed “lab on a chip”. They report that the microfluidic device is reconfigurable and useful for a wide range of applications – all at the click of a button.

Potential applications include making battery materials and electronic devices, and screening drug candidates.

“Our 3D-printed device can be programmed to carry out multistep, complex chemical reactions on demand,” explained Brett Helms, who led the study. “What’s even more amazing is that this versatile platform can be reconfigured to efficiently and precisely combine molecules to form very specific products.”

“Such devices may also be arrayed to generate deep or dark data for machine learning… to build knowledge and understanding from chemical logic.”

To create the device, the group designed a patterned glass substrate. Two polymer-containing liquids are then printed onto the surface – one contains clay and the other polymers. Within milliseconds, a thin channel of ~1mm in diameter is formed at the interface. Catalysts can then be placed in different channels, and bridges 3D-printed to connect the channels in a specific order. This can be computer-controlled and used to make molecules.

“The form and functions of these devices are only limited by the imagination of the researcher,” explained Helms. “Autonomous synthesis is an emerging area of interest in the chemistry and materials communities, and our technique for 3D-printing devices for all-liquid flow chemistry could help to play an important role in establishing the field.”

-

The future of cancer diagnosis could be in the veins

-

Cardiac tissue cultures – out now in 3D!

-

3D cell culture with Richard Eglen

The device furthers previous research at Berkeley, where a new technique was developed for printing liquid structures into another liquid. “…it occurred to us: if we can print liquids in defined channels and flow contents through them without destroying them, then we could make useful fluidic devices for a wide range of applications,” Helms commented.

The team feels the devices also have potential outside of chemistry. “The potential for this system to exhibit autonomous learning is evident,” the authors noted. “Such devices may also be arrayed to generate deep or dark data for machine learning… to build knowledge and understanding from chemical logic.”

Next, however, the team intends to electrify the device’s walls. “With our technique, we think it should also be possible to create all-liquid circuitry, fuel cells, and even batteries,” concluded Helms. “It’s been really exciting for our team to combine fluidics and flow chemistry in a way that is both user-friendly and user-programmable.”