Causing a buzz with insect-derived bioplastics

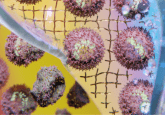

Researchers are optimizing the process of extracting chitin from black soldier fly carcasses, which can be used to synthesize biodegradable bioplastics.

Using insects to make plastics that are biodegradable and can be recycled as feed for the insects themselves may sound like science fiction but it is closer to becoming reality than you might have thought. In an interview at the American Chemical Society Fall 2023 meeting (13–17 August 2023; San Francisco, CA, USA), Karen Wooley, a Principal Investigator at Texas Agricultural and Mechanical University (TX, USA), and Cassidy Tibbetts, a graduate student in Wooley’s lab, discussed their research in isolating insect-derived chemicals and converting these products into functional bioplastics.

Current techniques to convert biomass into biodegradable polymers utilize materials including sugar cane and cellulose from trees; however, these resources are also required for food, fuel and construction. As an alternative source without these competing applications, Jeff Tomberlin, a colleague from the Department of Entomology, proposed the possibility of using chitin harvested from insects, a key polymer that strengthens exoskeletons. Insects are ideal candidates as cost-efficient biomaterial sources due to their short life cycles and low requirements of land, water and nutrients.

Black soldier fly larvae, rich in protein and essential fatty acids, are already widely used in agricultural feeds. These flies are increasingly bred for their larvae; however, adult flies only survive for about a week and are discarded. So, the researchers investigated the possibility of using this waste product with the goal of creating a cyclical system from black soldier flies. “Ultimately, we’d like the insects to eat the waste plastic as their food source, and then we would harvest them again and collect their components to make new plastics,” stated Wooley.

Getting to the root of mangrove RNA isolation

Getting to the root of mangrove RNA isolation

Scientists have optimized a protocol to achieve a higher quantity and quality of RNA isolated from mangrove root tissues.

Chitin is already extracted from the shells of shellfish and used in various manufacturing processes, but extraction from adult insects has not yet been developed. Wooley’s group has been optimizing a four-step isolation process that involves rinsing, drying and grinding the fly carcasses to a fine powder. This powder is then demineralized, deproteinated and decolorized to yield purified chitin. Currently, the process has a final chitin yield, relative to the starting biomass, of approximately 6%, with scope to improve this yield to “probably maximum 8-10% based on previous literature”, explained Tibbetts.

Another postgraduate student, Hongming Guo, has developed downstream processes that deacetylate the chitin to form chitosan and install functional groups to allow crosslinking of the D-glucosamine groups. The resultant matrix forms a superabsorbent hydrogel, capable of absorbing up to 47 times its own mass of water within 1 minute. This water is stored within the hydrogel, which is biodegradable and breaks down to release the water and nutrients over time. Wooley foresees potential uses of this hydrogel in agriculture and flood prevention, as well as water storage for drought mitigation.

Tibbetts added that chitin and chitosan both, “have massive uses in pretty much every industry from medical, cosmetic, as well as plastics. Right now, we are focussing on super-absorbent hydrogels, but the applications are truly endless.”

The potential of insect-derived chitin is not limited to hydrogels, with previous research suggesting a wide range of potential applications including use as a hemostatic agent for clotting blood that is then bioabsorbable. “And that is just for the chitin that’s abundant in the flies, there are also lipids and proteins and other components that we can harvest in later stages,” commented Wooley.

This research is still in its early stages and Wooley and her group will continue to optimize the harvesting process of chitin from black soldier fly carcasses and ensure it is scalable, as well as explore the chemical modifications to turn the building blocks into biodegradable materials.